The minimal amount of components which might be assembled for each hour is 50. That is certainly In case you are using the Handbook (hand) SMT machine.

A bulk from the greater achievement price of applying Surface Mount Technology (SMT) machines relies on the inputs of different machines Employed in the procedure.

Our SMT equipment supplies high-velocity assembly capabilities with out sacrificing precision, allowing us to fulfill the needs of substantial-quantity manufacturing. This effectiveness is essential for substantial creation operates, enabling us to take care of excellent whilst meeting tight deadlines.

This is Along with The point that Europlacer manufactures these machines to suit into your organization needs.

This SMT machine is largely used for enabling solder reflow in the Surface Mount Machine (SMD) into the circuit board. This is often finished following the reflow soldering is finished with solder paste.

These machines are generally applied due to higher precisions, various use situations/purposes, and The range of Digital factors that may be used on them.

Ground breaking Merchandise: Our range is not only reducing-edge; From innovative tech to timeless classics, we offer a spectrum of items that redefine excellence.

Other than, the IPC 9850 velocity or score typical must do with the general tips for the circuit board arrays plus the component blend.

We wouldn’t fall short to say the decide on-and-put machine you should buy need to be the one that has programming application, as well as a Laptop or computer. Both of these will go a long way to take care of the ongoing repetition of your ingredient placements.

M10 Lead cost-free Reflow oven is specially suitable for mid-high quantity creation. ten higher and ten bottom forced sizzling air convection zones make it possible for superior quality guide-free of charge soldering with uniform heating and exceptional approach balance Temperature accuracy of ±1°C, ensure the finest temperature control over the Printed Circuit Board surface mount technology machine Assembly

Inspections methods are designed for each pre-reflow and post-reflow inspection masking an extensive listing of element and solder joint defect types. Watch Much more Dry Cabinets

Worthy of point out is that guide pick-and-position machines in many cases are used for modular PCB creation requirements. The manual machines can even be utilised when You will find there's need to personalize the factors for top-velocity, unattended operations.

The 1st SMT machine for new manufacturing unit, I like to recommend a 6 heads decide on and palce machine PPM-C400GS+. As generation ability needs improve, new 6-head or eight-head placement machine can be seamlessly built-in into the prevailing manufacturing line to enhance performance and throughput, as illustrated during the figure under.

AOI plays a crucial part from the SMT creation line. Its Most important perform is to examine printed circuit boards (PCBs) for defects and anomalies once the soldering system.

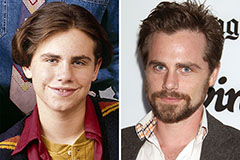

Rider Strong Then & Now!

Rider Strong Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Robbie Rist Then & Now!

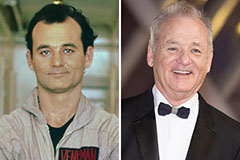

Robbie Rist Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!